inquiry@kinocranes.com

inquiry@kinocranes.com +86-15993036980

+86-15993036980

inquiry@kinocranes.com

inquiry@kinocranes.com +86-15993036980

+86-15993036980Henan Kino Cranes Co., Ltd

No.730, Xinghai Center, Hongqi District, Xinxiang, Henan, China

Tel: +86-373-3809941

M/P: +86-15993036980

E-mail: inquiry@kinocranes.com

Official Website: www.kinocranes.com

The previous overhead cranes used bare angle iron or copper rod conductive rails. Although this power supply method can be used, its performance and aspects are not ideal. At present, there are mainly the following types of conductive lines on the market: seamless slide wire, enclosed conductor rail and single pole bus bar.

1.Seamless slide wire: The seamless slid wire is powered by oxygen-free copper, which has better conductivity, good contact, convenient in installation, replacement and transportation. Besides, it is not easy to wear and damaged, resulted in a longer service life. The seamless copper core is tightly combined with the plastic shell, so that preventing poor contact caused by vibration. Compared with the traditional power supply method. Because of its convenience and high cost effectiveness, it is loved by many users.

2.Enclosed conductor rail: The enclosed conductor rail is generally 4 meters long and cannot be bent. Its electrical conductivity and coefficient are higher than that of seamless slide wire, and the waterproof effect is also better. However, since the shell is made of hard plastic, it is easy to be damaged during handling and installation, and the process during installation is also complicated. The price is relatively more expensive than that of seamless slide wire, so it is not widely used than the first type-seamless slide wire.

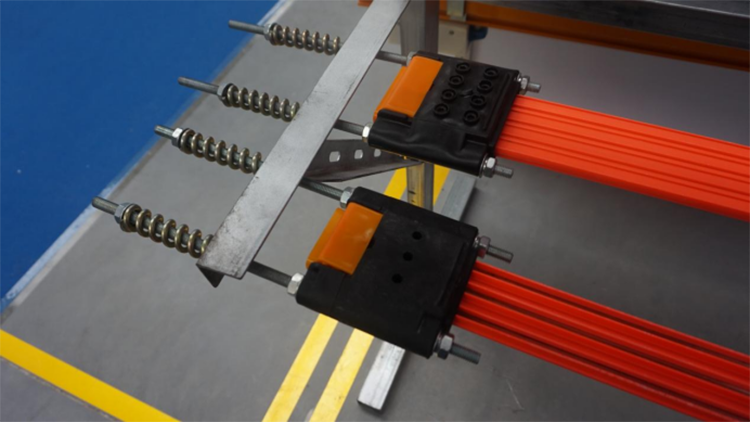

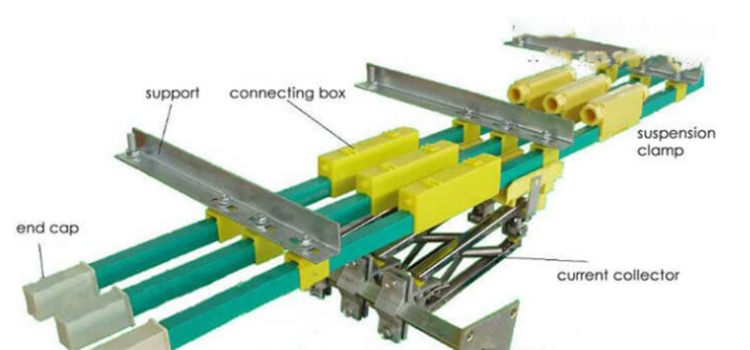

3.Single pole bus bar: The single pole bus bar is often used on large-tonnage overhead cranes. It is composed of guide rails, current collectors, isolators, protective sleeve, hangers, connectors, fixed clips, end caps, and thermal compensation equipment. The performance is best among the three types and the work is very reliable. Such as the appearance of poor power contact will not occur. It can withstand relatively large short-circuit impulse current in harsh environments such as high temperature, high humidity and high voltage. The mechanical strength is high, and it is very difficult to bend and deform resulted failure thanks to its high rigidity. Its long service life thanks to the large heat dissipation area.

Most of the faults of the crane conductive line are due to poor contact, which is caused by insufficient spring force of the collector or incorrect installation. In order to better maintain the conductive line, the wear resistance of the collector and the chamfering of the brush can be increased, and then the pressure of the collector spring can be enhanced to ensure that the current collector is smoothly running. Moreover, when using the current collector, be sure not to wrong wiring, so as to avoid short circuit, burn out the current collector and conductive line. It is required to check and replace the current collector carbon brushes frequently. Observe whether the conduit is damaged or deformed very often, and replace it in time to avoid leakage. If the crane conductive line that has been used for a long time, a large amount of dust will be accumulated in the inner conduit. It must be cleaned regularly. It is recommended to use a blower to clean it, and it is strictly forbidden to wipe it with water.