Quality Control

Steel Structure Control

KENANCRANES will inspect the steel quality and welding quality to ensure that the raw materials and welding quality meet international standards.

Mechanism Control

On all mechanisms such as crane wheels, hooks, and wire ropes, technical requirements and performance tests will be carried out in strict accordance with international standards

Assembly Control

There are strict registration records for the span inspection, painting and loading test of the crane. For example, the stiffness and camber of the crane span, the thickness of the paint film, dynamic, static, and no-load tests, etc., all links are strictly checked.

Crane Inspection Checklist and Tests

Radiographic testing, ultrasonic testing, penetration testing, magnetic testing, coating testing, metal hardness testing

Purchased Parts Brand

ABB, Siemens, SEW, Schneider, SKF, DSR, etc.

Quality Control

After testing and validation, a final inspection is conducted to ensure that the crane meets all of the required quality standards and specifications such as deflection, motion speeds, capacity etc. Any defects or issues are identified and addressed before the crane is released for shipment.

Ultrasonic Thickness Detector | Steels Detection

All steel after the arrival shall be inspected on material, size, thickness. Thickness detection by ultrasonic thickness. Material report will be issued by the inspection team. If the QC group found unqualified, the steel cannot put in storage. Return notice issued by the inspection engineer directly to purchasing department. |

|

|

Magnetic Defect Detector | Weld Inspection

All the joint panel welding seam, web plate fillet weld are strictly according to drawings and European Crane Process Standard. Use RT/MT/UT/PT nondestructive inspection and issue relevant inspection report. Measure and mark the unqualified parts and let no doubts pass. |

|

|

Leeb Hardness Tester | Wheel hardness, roughness test

All the wheels and shaft machining parts need strict inspection for hardness, roughness, dimensions etc. Ensuring every parts conform to design specifications. |

|

|

Paint Film Thickness Gauge | Paint film thickness detection

Advanced surface treatment process and Epoxy zinc-rich coatings to ensure our crane won’t have paint falling off or color fading. The key is our strict inspection and quality control. |

|

|

Level Gauge | Pre-install Inspection

Although we have thorough quality control to each part in the producing process, we take pre-install inspection to every crane before delivery. The crane will be pre-installed and measured as per inspection process and design parameters. The key inspection parts are span, length, beam deflection etc. |

|

|

Third Party Inspection

KINOCRANES not only has complete process inspection and delivery inspection, for the critical components, the factory invite authority organization to do the third party inspection, ensuring that each component reaches design requirements.

Also the factory can do third party inspection under user’s requirement by SGS, TUV or BV international inspection organization. |

|

|

|

|

|

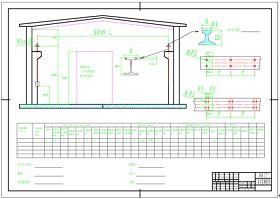

Site inspection

KINOCRANES have a professional installation team with rich crane installation experiences. Different mature installation proposal suit for different workshops and steel structures. Before installation, our site engineer will check and measure the workshops, such as the H-beam height, workshop height, span, installation accuracy etc to ensure the smooth and successful crane installation. |

|

|  |

|

Total Station Laser Range Finder

|

|

|

inquiry@kinocranes.com

inquiry@kinocranes.com +86-15993036980

+86-15993036980 inquiry@kinocranes.com

inquiry@kinocranes.com +86-15993036980

+86-15993036980