inquiry@kinocranes.com

inquiry@kinocranes.com +86-15993036980

+86-15993036980

inquiry@kinocranes.com

inquiry@kinocranes.com +86-15993036980

+86-15993036980Henan Kino Cranes Co., Ltd

No.730, Xinghai Center, Hongqi District, Xinxiang, Henan, China

Tel: +86-373-3809941

M/P: +86-15993036980

E-mail: inquiry@kinocranes.com

Official Website: www.kinocranes.com

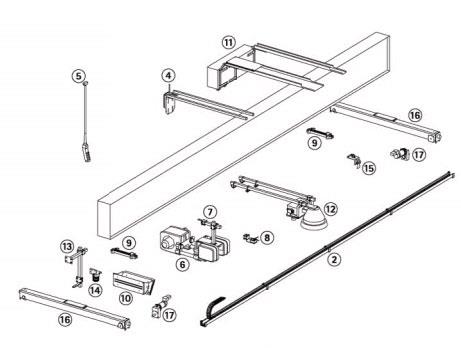

| 1.Trolley power festoon system 2.Trolley power drag chain system 3.Control pendant with emergency switch 4.Remote control including transmitter and receiver 5.Pendant for backup 6.Lifting mechanism 7.Trolley cable bracket 8.Cross & long travel limit switch 9.Trolley travelling stopper |

10.load display screen 11.long travelling cabinet 12.lighting under beam 13.long travelling power cable bracket 14.alarm light 15.speaker 16.end carriage 17.long travelling three-in-one driven gear motor |  |

Double girder overhead crane of pendant control, festoon power supply

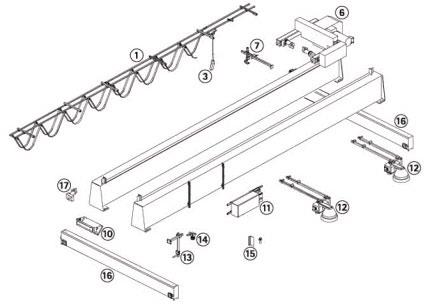

Main girder |

End beam for double girder EOT crane |

End beam for single girder EOT crane |

►

The main beam adopts bias-rail box-type structure and connects with end beam by high-strength bolt ensuring easy transportation. The professional processing equipments ensure the connection accuracy of main end beam, making crane run steadily.

►

Trolley of crane uses open compact winching structure, of which with medium and small tonnage also can use new hoist trolley.

►

Long crane & cross trolley travelling mechanism adopt Europe three in one drive type, harden tooth surface gear box. good performance in compact structure, low noise, none oil leakage and longer service life.

►

As using new compact trolley and high-strength material, it has small overall dimension and light weight, compared with traditional crane, which can decrease the height of factory building and reduce the cost.

►

Modular design has short design period and high generalization, which can improve the utilization of components.

►

With compact structure, low clearance, small dimension and large application scope, it can improve production efficiency.

►

Full variable-frequency control runs steadily without any impaction. Run with heavy load at low speed and light load at high speed, it can save energy and reduce consumption.

Main Beam / End Carriages:

★ The main beam is a partial rail box beam or H type steel beam, steel plate material is Q345-B; vertical deflection is L / 800; all steel plates are pretreated with shot blasting to Sa2.5 Class; the steel are inspected and cleaned well before welding (MIG) or semiautomatic welding; all welds are ray-free nondestructive testing; double-beam cranes are equipped with maintenance platforms (maintenance walkways) along the main vehicle driving side.

★ End carriages are the rectangular steel pipe and welding molding in a CNC machine tool positioning processing, steel material Q345-B; each end carriage is equipped with a double wheel rim wheel group» buffer and anti-derailment protection device.

★ The main beam and the end carriages adopts high strength bolts to facilitate the transport and installation to ensure that the whole crane operates accurately and smoothly.

Maintenance Platform:

Along with the outside of driving main beam, maintenance platform set for easy maintenance

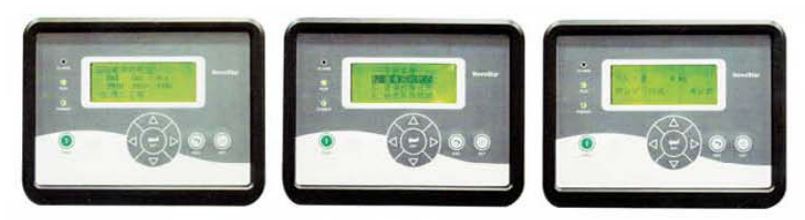

The dedicated frequency converter for hoisting and travelling mechanism enables real-time conmmunication,and becomes a hoist control center through the device.

Safety Monitoring

Sinokocranes company develops safety monitoring unit specially for the SM type double girder overhead trolley» which achieves a variety of functions according to the demand of users.

★ To calculate the remaining safety working circle of hoisting mechanism

★ To accumulate lifting working hours

★ To accumulate overload times

★ To accumulate lifting motor start times

★ Overheat protection and alarm for lifting motor

★ Overload protection and alarm

★ To alarm for brake plate thickness

★ To display fault information and maintenance tips

Crane joint design between main girder and end carriage:

Main girder and end carriage are connected by high strength screw to ensure safe and stable running of crane and make transportation, installation and maintenance easy.

Optimized structural design, maximize the space of different workshops

Standard connection |

Low headroom connection |

Intermediate connection type I |

Intermediate connection type II |

Intermediate connection type III |

Overload Protection :

Core components of hoisting mechanism - electronic pressure sensor , imported originally from germany. Accurate and reliable electronic overload protection can prevent overloading effectively during operation and enhance the safety of the equipment. the overload protection device cooperates well with the control circuit , to prevent further load increasing and ensure that the load can be declined safety.

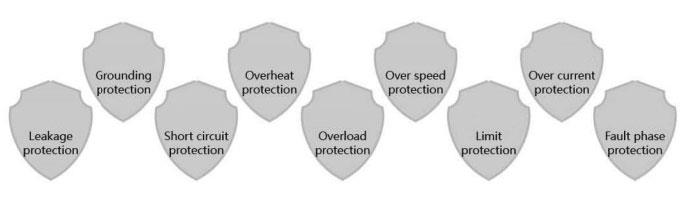

The Crane Has A Safety Specification Required For The Protection Function:

* Circult control is outputed by the transformer , with control vollage of 48v , this ensures sufficient power output when the hoisting . cross travelling and long travelling mechanisms runs at the same time .

* Control box protection class is IP55 , with waterproof protection , ambient temperature<45°C , hurricity <90% , the main voltage supply for crane is 380v ( 10% ) , 50hz ( 5% ) a . C . 3 Phases .

Frequency Converter Control/ VVVF:

* Ensure accurate positioning of the load * Adjustable acceleration * Smoothly braking * Anti-swing * Expand the speed * Easy operate

Trolley Drag Chain System : Trolley drag chain system includes : cable chain , trunking and base . * Cable wiring neat and compact . * Installed in the main driven side of the beam , convenient maintenance |

Trolley Festoon System : Trolley festoon system includes : flexible flat cable , cable trolley (with bracket), sliding rail; the flat cables adopt rubber with good elasticity. The cable is fixed and hung on the bracket of cable trolley, the cable trolley travel in the sliding rail, c type sliding track is connected to main girder through support bracket. The cable trolley bracket makes the cable not interfere with each other in any case . |