inquiry@kinocranes.com

inquiry@kinocranes.com +86-15993036980

+86-15993036980

inquiry@kinocranes.com

inquiry@kinocranes.com +86-15993036980

+86-15993036980Henan Kino Cranes Co., Ltd

No.730, Xinghai Center, Hongqi District, Xinxiang, Henan, China

Tel: +86-373-3809941

M/P: +86-15993036980

E-mail: inquiry@kinocranes.com

Official Website: www.kinocranes.com

Working system is related to mechanical life. When you choose crane, you should select corresponding crane FEM working system according to the real working condition, so as to make your investment more reasonable. Before you choose FEM working system, two aspects need to be considered: load type (scope of load bearing) (K) and daily average operating time (Tm)

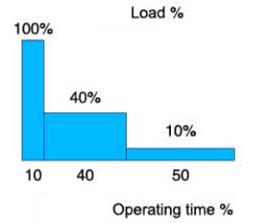

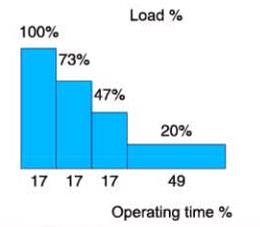

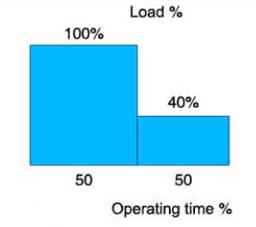

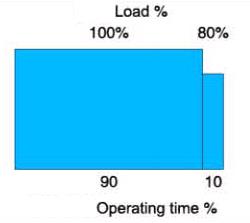

Load type(scope of load bearing)

Light type(k≤0.5) Occasionally lifting with full load, usually lifting with light load, fixed load is low. |  |

Middle type(0.5< k ≤0.63) Occasionally lifting with full load, usually lifting light load,fixed load is in average. |  |

| Heavy type(0.63 <k ≤0.8) Repeatedly lifting with full load, usually using average weight load, fixed load is heavy. |  |

| Extra heavy type(0.8<k<1) Usually lifting with full load, fixed load is heavy. |  |

Daily Average working time(TM):TM means daily average working time, including load and empty load.

FEM woking duty estimated data.

Load level | Average performance time (hour) | ||||||

Maintenance | K | < 0_5h | < lh | < 2h | < 4h | < 8h | < 16h |

Light type | K<0.5 | 一 | ICm | lBm | lAm | 2m | 3m |

Middle type | 0.5 < K<0.63 | ICm | lBm | lAm | 2m | 3m | 4m |

Heavy type | 0.63 < K<0.8 | lBm | lAm | 2m | 3m | 4m | 5m |

Extra heavy type | 0.8 < K < 1 | lAm | 2m | 3m | 4m | 5m | 一 |

FEM working duty examination

Need to inspect the motor load and number of starts of every hour

(Lifting time + down time)

Motor load= ------------------------------------------------------------------

(Lifting time + standby time + down time +standby time

| Working duty | lBm | lAm | 2m | 3m | 4m |

| Motor load(ED) | 25% | 30% | 40% | 50% | 60% |

| Numbers of starts of every hour | 150 | 180 | 240 | 300 | 360 |

| Operating time with full load of one year/250days | 400 | 800 | 1600 | 3200 | 6300 |

FEM/ISO

| FEM working duty | 1Bm | 1Am | 2m | 3m | 4m |

| ISO working duty | M3 | M4 | M5 | M6 | M7 |

Crane Working Class Selection

Crane Classification | Typical Installation | Lifts per/hr. | Average Lift | Shift | Typical Workload | Key Points |

Class A Standby or Infrequent Service | Power Houses Public Utilites Turbine Rooms Motor Rooms Transformer Stations | 0-2 | 10 ft. | Single Shift Operation | Precise handling at slow speeds with idle periods between lifts Capacity loads may be handled for intial installation of equipment and for Infrequent maintenance | H1 Hoist Maintenance crane in machine house Used only occasionally |

Class B Light Service | Repair Shops Light Assembly Operations Light Warehousing | 2-5 | 10 ft. | Single Shift Operation | Loads vary from no load to occasional full rated loads | ?H2 Hoist Light service requirements Slow speed |

Class C Moderate Service | Machine Shops Paper Mills Machine Rooms | 5- 10 | 15 ft. | Single Shift Operation | Average load is 50% of rated load 50% of less of the lifts are at the rated capacity | ?H3 Hoist Minimum 1.15 service factor on bridge motion 5,000 L-10 bearing life |

Class D Heavy Service | Heavy Machine Shops Foundries Fabricating Plants Steel Warehouses Container Yards Lumber Mills Stanadard Duty Bucket & Magnet Operations | 10-20 | 15 ft. | 1 - 2 Shift Operation | ?Average loads approaching 50% are continuously handled 50% of less of the lifts are at the rated capacity | ?H4 Hoist Minimum 1.3 service factor on bridge motion 10,000 L-10 bearing life Lift the maximum capacity with 30% frequency Typically faster speeds over Class C A Built-Up Hoist is typically used in this type of application and is tailored towards a specific application with a heavy duty cycle to handle demanding needs. |

Class E Severe Service | Magnet Bucket Magnet/Bucket Combo Scrap Yards Cement Mills Lumber Mills Fertilizer Plans Container Handling | 20+ | 20+ft. | 24/7 Continuously | Continuous use at/or near capacity | ?H4+ Hoist Minimum 1.75 service factor on bridge motion 20,000 L-10 bearing life Continuously lifts at the maximum capacity Typically faster speeds over Class C and D A Built-Up Hoist is typically used in this type of application and is tailored towards a specific application with a heavy duty cycle to handle demanding needs. |

Hoist Classification | Corresponding Crane Class | Corresponding Crane Class | |||

FEM | HMI | ISO | CMAA | DIN 15018 & SIM. | EXAMPLE |

1Cm | H1 | M2 | CLASS A | H1/B2 |

|

1Bm | H2 | M3 | CLASSB | H1/B2 |

|

1Am | H3 | M4 | CLASSC | H2/B3 |

|

2m | H4 | M5 | CLASSD | H2/B3 | Heavy duty crane, 2 shift operation |

3m | H4 | M6 | CLASS D | H2/B3 or H3/B4 | Med/heavy duty work shop crane |

4m | H4 or H5 | M7 | CLASS D or CLASSE | H3/B4 or H4/H6 | Very heavy duty crane |

KEY:

FEM - Federation Europeenne de la Manutention (European Federation of Material Handling)

HMI - Hoist Manufacturers Institute ISO - International Organization for Standardization CMAA - Crane Manufacturers Association of America DIN - Federation Europeenne de la Manutention (German Institute for Standardization)