inquiry@kinocranes.com

inquiry@kinocranes.com +86-15993036980

+86-15993036980

inquiry@kinocranes.com

inquiry@kinocranes.com +86-15993036980

+86-15993036980Henan Kino Cranes Co., Ltd

No.730, Xinghai Center, Hongqi District, Xinxiang, Henan, China

Tel: +86-373-3809941

M/P: +86-15993036980

E-mail: inquiry@kinocranes.com

Official Website: www.kinocranes.com

CRANE DUTY GROUP

Crane duty groups are a set of service classifications defined based on the frequency of use and percentage of the lifts at or near rated capacity. Two cranes with the same rated capacity and span may differ in their “average load intensity” and/or “expected loading cycles”; hence they will likely differ in their design.

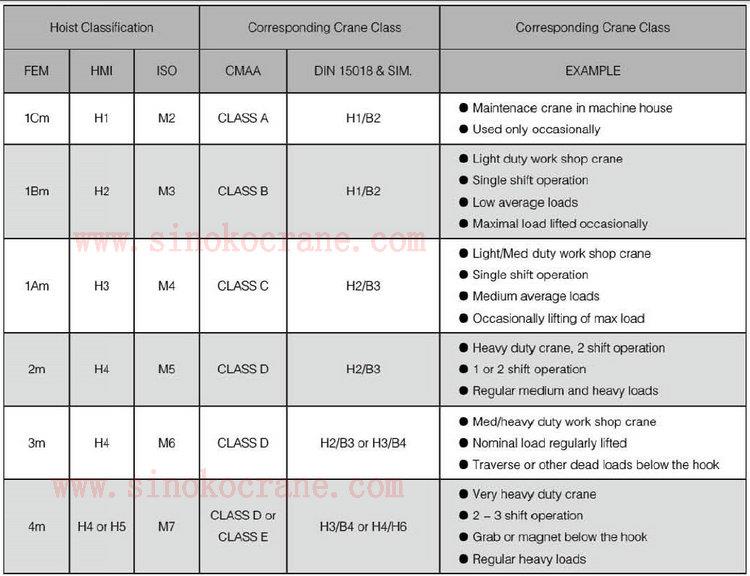

Various standards exist to rate the “service class” of a crane and/or hoist. The Crane Manufacturers Association of America (CMAA) classifies the bridge cranes according to average load intensities and number of cycles. On the other hand, the International Organization for Standardization (ISO), the European Federation Standard (FEM) and the Hoist Manufactures Institute (HMI) all classify hoists according to more rigorous requirements, which include the number of starts and the maximum running time per hour. The following is a short description:

CMAA SERVICE CLASSIFICATION

There are six different classifications of cranes by CMAA based on the duty cycle of crane.

1. Class A (Stand-by or Infrequent Service) - This crane is the lightest crane as far as the duty cycle is concerned. This service class covers cranes where precise handlings of equipment at slow speed with long idle periods between lifts are required. Capacity loads may be handled for initial installation of equipment and for infrequent maintenance. Examples of the use of Class A cranes include a transformer station, power houses, turbine halls, motor rooms, public utilities, etc.

2. Class B (Light Service) - This service class covers cranes where service requirements are light and speed is slow. Loads may vary from no load to

occasional full rated loads with 2 to 5 lifts per hour, averaging 10 feet (3 meters) per lift. Examples of class B cranes include service buildings, light assembly operations, repair and maintenance shops, light ware housing, etc.

3. Class C (Moderate Service) - Class C cranes are those cranes whose service requirements are deemed moderate. These cranes handle loads averaging 50 percent of the rated capacity, with 5 to 10 lifts per hour averaging 15 feet (4.6 meters), with a maximum of 50 percent of the lifts at rated capacity. Examples of class C cranes are the cranes usually used in paper mill machine rooms, machine shops, etc.

4. Class D (Heavy Service) - In class D crane service, loads approaching 50 percent of the rated capacity is handled constantly during the work period. High speeds are desirable for this type of service with 10 to 20 lifts per hour averaging 15 feet, with not more than 65 percent of the lifts at rated capacity. Typical examples of cranes with heavy service are steel warehouses, foundries, fabricating shops, heavy machine shops container yards, lumber mills, etc. Cranes may be with standard duty bucket or magnet operations where heavy duty production is required.

5. Class E (Severe Service) - Cranes with class E service are capable of handling loads approaching the rated capacity throughout their lives, with 20 or more lifts per hour at or near the rated capacity. Application of cranes with class E include magnet, bucket, or magnet/bucket combination cranes on fertilizer plants, cement plants, scrap yards, lumber mills, container handling, etc.

6. Class F (Continuous Severe Service) - Cranes with class F service are capable of handling loads approaching rated capacity continuously under severe service conditions throughout their lives. Typical examples of such cranes include custom designed specialty cranes essential for performing the critical work tasks affecting the total production facilities. This type of crane must provide the highest reliability with special attention to ease of maintenance features.

In many cases, the classification can easily be determined; however, the code also provides a table that can be used to determine the classification based on more detailed information such as load classes and load cycles.

CRANE DUTY GROUP

Crane duty groups are a set of service classifications defined based on the frequency of use and percentage of the lifts at or near rated capacity. Two cranes with the same rated capacity and span may differ in their “average load intensity” and/or “expected loading cycles”; hence they will likely differ in their design.

Various standards exist to rate the “service class” of a crane and/or hoist. The Crane Manufacturers Association of America (CMAA) classifies the bridge cranes according to average load intensities and number of cycles. On the other hand, the International Organization for Standardization (ISO), the European Federation Standard (FEM) and the Hoist Manufactures Institute (HMI) all classify hoists according to more rigorous requirements, which include the number of starts and the maximum running time per hour. The following is a short description:

CMAA SERVICE CLASSIFICATION

There are six different classifications of cranes by CMAA based on the duty cycle of crane.

1. Class A (Stand-by or Infrequent Service) - This crane is the lightest crane as far as the duty cycle is concerned. This service class covers cranes where precise handlings of equipment at slow speed with long idle periods between lifts are required. Capacity loads may be handled for initial installation of equipment and for infrequent maintenance. Examples of the use of Class A cranes include a transformer station, power houses, turbine halls, motor rooms, public utilities, etc.

2. Class B (Light Service) - This service class covers cranes where service requirements are light and speed is slow. Loads may vary from no load to

occasional full rated loads with 2 to 5 lifts per hour, averaging 10 feet (3 meters) per lift. Examples of class B cranes include service buildings, light assembly operations, repair and maintenance shops, light ware housing, etc.

3. Class C (Moderate Service) - Class C cranes are those cranes whose service requirements are deemed moderate. These cranes handle loads averaging 50 percent of the rated capacity, with 5 to 10 lifts per hour averaging 15 feet (4.6 meters), with a maximum of 50 percent of the lifts at rated capacity. Examples of class C cranes are the cranes usually used in paper mill machine rooms, machine shops, etc.

4. Class D (Heavy Service) - In class D crane service, loads approaching 50 percent of the rated capacity is handled constantly during the work period. High speeds are desirable for this type of service with 10 to 20 lifts per hour averaging 15 feet, with not more than 65 percent of the lifts at rated capacity. Typical examples of cranes with heavy service are steel warehouses, foundries, fabricating shops, heavy machine shops container yards, lumber mills, etc. Cranes may be with standard duty bucket or magnet operations where heavy duty production is required.

5. Class E (Severe Service) - Cranes with class E service are capable of handling loads approaching the rated capacity throughout their lives, with 20 or more lifts per hour at or near the rated capacity. Application of cranes with class E include magnet, bucket, or magnet/bucket combination cranes on fertilizer plants, cement plants, scrap yards, lumber mills, container handling, etc.

6. Class F (Continuous Severe Service) - Cranes with class F service are capable of handling loads approaching rated capacity continuously under severe service conditions throughout their lives. Typical examples of such cranes include custom designed specialty cranes essential for performing the critical work tasks affecting the total production facilities. This type of crane must provide the highest reliability with special attention to ease of maintenance features.

In many cases, the classification can easily be determined; however, the code also provides a table that can be used to determine the classification based on more detailed information such as load classes and load cycles.